The foundation of Interfuse Manufacturing is built upon a history of 40 years of Machining experience and technology. We offer complete CNC machining operations to provide a final manufactured component to our customers. Not only are we able to complete the entire machining process, our vast experience allows us to troubleshoot difficult issues and improve the overall fit of final components.

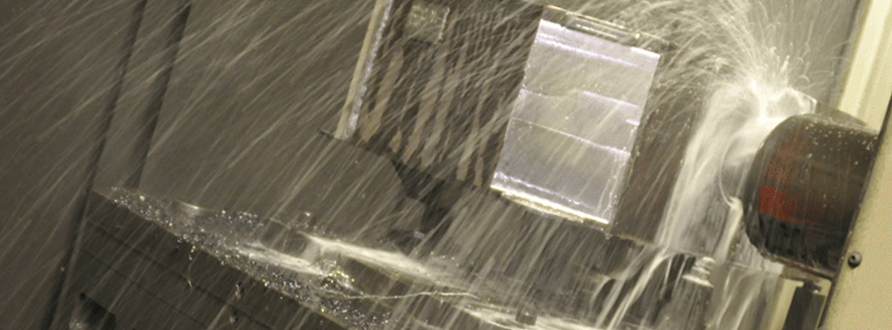

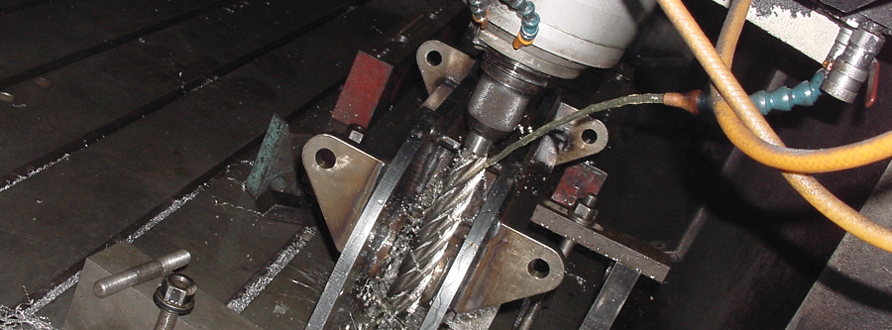

We use state-of-the art CAD-CAM technology in UNIGRAPHICS to achieve complex contour machining. We also have the ability to translate all standard engineering file formats and build quality parts to exact customer specifications. Before proceeding to full production, we always monitor and track all cutter paths to verify accuracy.

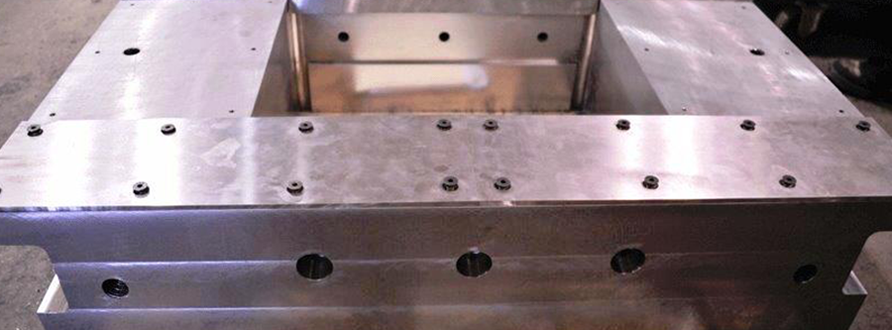

Our high-speed, high-performance machining capabilities enable us to combine numerous operations for greater efficiency. Our CNC machinery is ideally suited for prototype, short run, and production quantities from a few pieces to several thousand. We have a strong history in machining molds for brick refractory, glass industries, and, more recently, machining welded fabrications and fabricated parts for multiple equipment industries. Interfuse has the capability to rotary, surface, ID, and OD grind specialty metals, such as tool steel and carbide, using advanced ceramics and armored diamond abrasives.

We also provide heat treating services, including atmosphere controlled furnaces, to provide scale-free parts, which are highly desirable on intricate die parts without any secondary operations. We are able to through-harden a range of tool steels, as well as oil-quenched steels. We provide thermal stress relieving, vibratory stress relieving, and annealing. All heat treating services are tracked with direct read charts and are inspected with appropriate Brinell and Rockwell testers.

Interfuse Manufacturing also provides cryogenic treatment of materials in conjunction with heat treating. This process will extend the life of a treated part up to three times longer than that of an untreated part and provide more stable and wear-resistant parts.

With the ability to engineer, fabricate, weld, and machine, what starts in our facility as raw metal, has the ability to ship as a complete manufactured component.

See our Welding and Fabricating capabilities.